Q-SNAP is the only secure fastener with stretch function. It is developed for covers and sprayhoods on boats and is perfect for all applications that require textiles to be tight and secure.

To even be resistant to seawater, Q-SNAP is made from high quality 316 stainless steel. The special ring spring in the socket is dimensionally stable and even more resistant to corrosion than SS 316.

Now even children and people with less strength in their hands can fix any tight cover. All thanks to the integrated lever of Q-SNAP.

It is just that bit of help to overcome the tension easily.

Installation is like a normal press fastener, using the same tools and dies as regular snaps. Time saving tools make it up to 4 times faster to install than other secured fasteners.

a connection to rely on

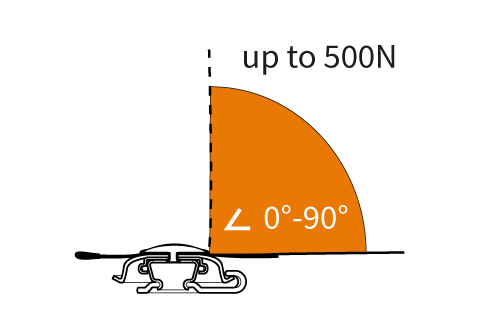

Cover makers using Q-SNAP can make a solid and tight cover that protects precious property or beloved ones properly. It won’t pop loose. Not even at 500N, no matter the angle between the fixed surface and the cover. Above all, it is the only secured fastener without moving parts, making it very durable and robust.

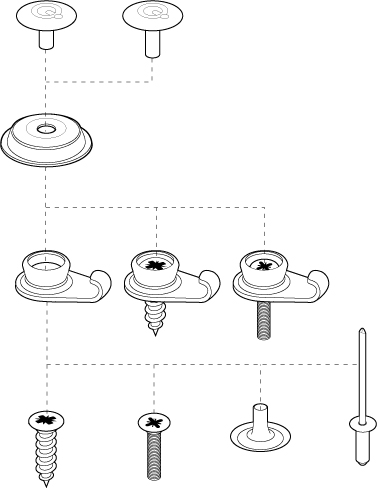

The patented Q-SNAP is just like a normal press-fastener, with 2 additional parts: a ring underneath the cloth and a gentle hook on deck. This combination turns the fastener into a secure connection that won’t pop loose, while it incorporates a stretch-function (lever). The cloth is stretched as you fix.

Q-SNAP is patented and a registered trademark.

The Q-cap is 15 mm. in diameter, is self-piercing and fully made of 316 stainless steel. It comes in different shaft-lengths and colour. It fits any standard 15 mm domed cap-socket die and it's best if they are hardened.

The Q-socket is an integrated socket with large ring in SS 316. Of course with the special CAF-spring inside for reliable performance over time and use.

The base part is called Q-stud and has a thin rubber layer underneath for 3 functions: refrains the stud from twisting after installation, forms a isolating layer between the 316 material and the base material (avoiding galvanic corrosion on e.g. aluminum) and it holds a fixing pre-assembled (1 item out of the box for convenience and speed of installation).

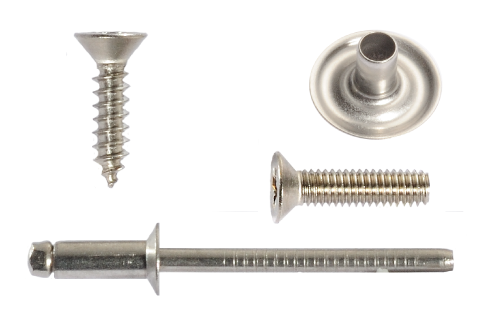

Since the lever function of Q-SNAP needs something rigid to push against, mostly the stud is applied by screws, machine screws or rivets. The self-tapping screw has an optimized thread for better hold in wood, polyester and aluminum. In some cases an eyelet is yet a working solution, like with a inflatable boat. Opening up dozens of applications on these types of objects.

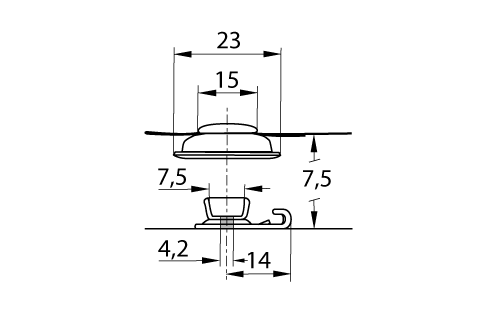

Dimensions are in mm.

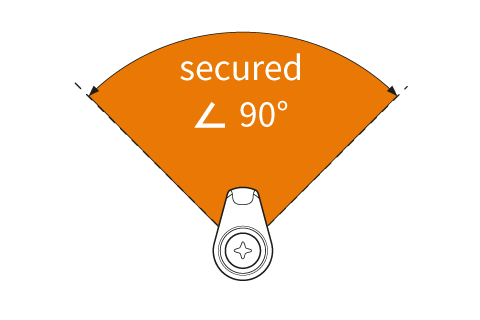

The Q-SNAP system offers a so-called 1/4-lock from the tensile force direction.

tested in different directions: from horizontal to vertical it holds until 3 layers of fabric tear apart.

Since Q-SNAP requires a 4 mm hole for the shaft to go through the fabric, there are hole punchers in all sorts available. For professional application, same tools and dies can be used in pliers, hand and automated machines for easy and quick (self-piercing) installation.

A smart tool to hold the q-stud in the right direction while screwing it into place.

Used for temporary fix the fabric on the q-studs during design and templating. Now you know exactly where to put the Q-cap and socket.

in case the cap and socket are already in the fabric this stud-marker is of help to point out the position of the q-stud.

Q-SNAP is available in packs of 10 pcs. per part and per colour. For the professional there is a 100 and 500 pack. Bulk is on request.

The DIY-kit carries 10 complete sets Q-SNAP incl. all tools and clear instructions.

For the professional that wants to test Q-SNAP on 1 or 2 jobs there is this Starter-Kit. It carries 50 complete sets in different variations incl. all tools, accessories and time-savers. There is only one chance for a first impression.

see detailed content

for more information and an overview of the assortment.

a touch tell more than a thousand words.

To see the standard colour range in real.